Personalized care in Newbury Park

We know visiting the dentist can be stressful. That is why our clinic focuses on clear, human, and patient-centered care.

As dentists in Newbury Park, we understand the needs of our community. We work to make every patient feel heard, comfortable, and confident in their treatment.

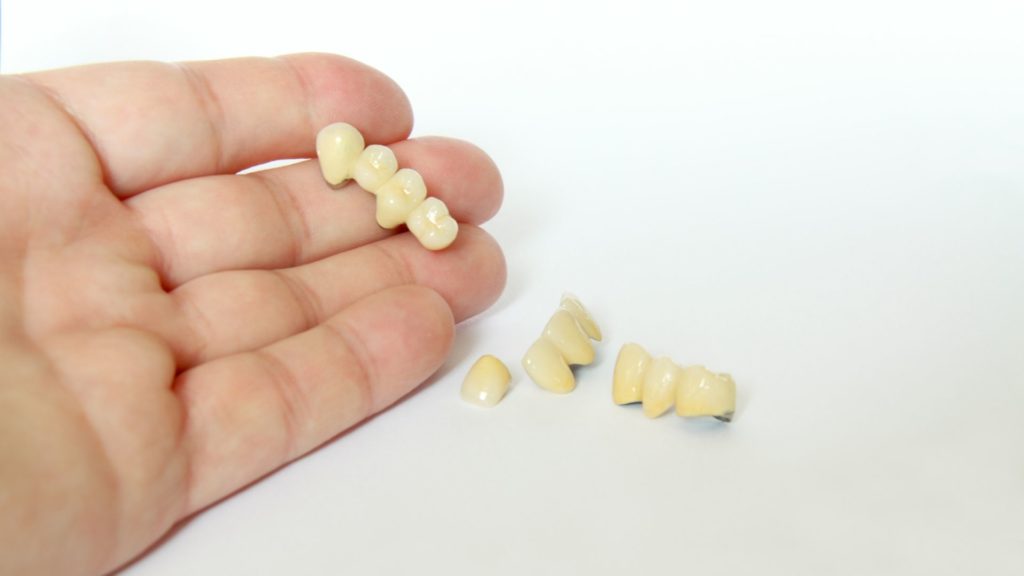

If you have a damaged tooth, pain when chewing, or just want to know if a porcelain crown is right for you, we invite you to visit us at Channel Islands Family Dental Office.

- We are located in Newbury Park.

- Book your appointment today.

- Take the first step to restore your smile.

Our team will be happy to help you find the best solution for your dental health.